About JBR Recovery LtdPrecious Metal Recovery and Refining including Silver, Gold, Platinum & Palladium Refining

|

JBR is a processor of materials containing silver, gold and other PGM metals. Our specialist skills have targeted secondary or waste materials, especially the photographic industry - the largest user of silver; but also include other source streams.Manufacturing processes and materials arising from partial refiners are our key sources of input material for treatment and refining. The materials received contain between 1.5 and 995 kgs of silver per tonne, frequently contain gold and other precious metals, and include wet residues; dry residues, powders or ashes; metallics; and materials requiring incineration or chemical treatment as a primary operation. JBR RECOVERY LTD The Environment Agency issue JBR with an Environmental Permit to operate its precious metal recovery processes . For more details refer to the Environment Section of the website. Our silver recovery process is based on a traditional pyrometallurgical smelting operation. Combustible materials are incinerated in controlled conditions to produce an ash in which the silver content has been retained. This ash is mixed with other silver bearing materials including Sweeps, Sludges and Residues which may have been calcined to remove both moisture and volatile organic compounds. The resultant mix is combined with lead and fluxes and charged into a shaft furnace. The reaction and combination of the charge produces a lead /silver alloy with a silver purity of about 50%. Sampling and assaying are key elements of our silver recovery process where the silver content is determined for each consignment of material received. The sampling can be witnessed. Assaying is carried out in our own laboratory according to classical fire assay techniques and universally accepted chemical methods. The JBR process, which operates with full environmental registration from the Environment Agency (refer to Environment page), is based within the industrial West Midlands and the site covers 2.05 acres. The process has been developed over time to provide an efficient and competitive service. For more information on Precious Metal Recovery, Silver recovery , Gold Refining and Platinum Refining please feel free to contact us on 0121 525 1691 |

|

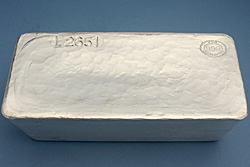

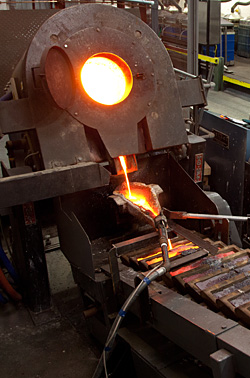

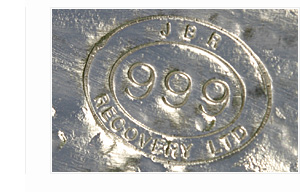

The alloy undergoes a further fire refining process where the lead is removed by preferential oxidation to produce high grade silver (98+%) and (litharge)lead oxide. The litharge is recycled and the silver is subjected to a chemical process which achieves a purity of 99.9+%. The final operation converts the 99.9%+ silver into 'Good Delivery' bars conforming to international standards and stamped as 999.

The alloy undergoes a further fire refining process where the lead is removed by preferential oxidation to produce high grade silver (98+%) and (litharge)lead oxide. The litharge is recycled and the silver is subjected to a chemical process which achieves a purity of 99.9+%. The final operation converts the 99.9%+ silver into 'Good Delivery' bars conforming to international standards and stamped as 999.